The current state of waste water treatment in the EU

Sewage treatment is facing challenges such as climate change, low resource efficiency and poor environmental and human protection. More than 30 million people are not connected to wastewater treatment plants (WWTP) in the EU yet. EU water body quality is still low ecologically and chemically not fulfilling current water directives. Moreover, new water pollutants are arisen (pharmaceuticals, drugs, microplastics, etc.).

For this reasons, collecting and treating wastewater has required huge investment across Europe in recent decades. However, EU water body quality status is still low ecologically and chemically. New innovative technologies must be brought to the market to overcome these challenges, increase water quality in rivers, lakes and seas and give raise to the advanced 21st century WWTP.

What are the main wastewater treatment processes?

Sewers collect sewage and transport it to a wastewater treatment plants. There, differing levels of treatment can be applied and usually include:

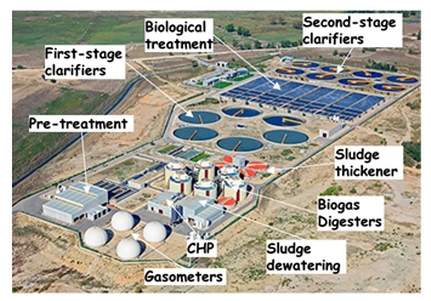

- Pre-treatment: physically removes large objects like rags and plastics, and smaller objects like grit from the wastewater. This prevents damage to the equipment further along the treatment process.

- Primary treatment: remove fine particles. Wastewater is held in a first clarifier or sediment tank where heavier solids can settle to the bottom, while any lighter solids and fat float to the surface. The settled and floating materials are separated and transported to stabilization, while the remaining liquid proceeds to secondary treatment. .

- Secondary treatment: the biological treatment removes the remaining organic matter, suspended solids and some of patogens and chemical substances. It’s made up of an oxidation tank where bacteria grow fed with the nitrogen and phosphorous contained in nutrients which are thus eliminated from water. Afterwards, a secondary clarifier or sedimentation tank removes the activated sludge composed of grown bacteria.

- Tertiary treatment: apply to remove the remaining nutrients when discharging into sensitive waters. Specific treatment techniques, such as disinfection, can be used to further remove bacteria, viruses, and parasites harmful to public health, or any remaining chemicals and harmful substances.

How SewaTOR can be installed on a wastewater treatment system?

Where can SEWATOR be installed in the sewage treatment plant?

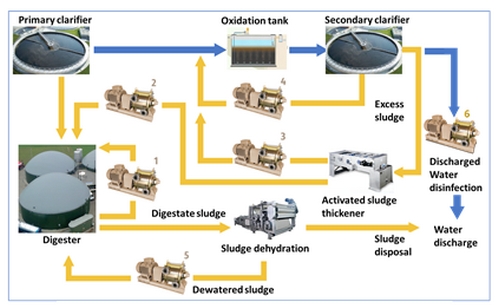

As Figure 3 shows, SewaTOR can be used at different locations within the WWTP:

- In recirculation on the anaerobic digester;

- In loading from thickener to digester;

- In recirculation from thickener to biological oxidation tank;

- In recirculation from secondary sedimentation tank to biological oxidation tank;

- In recirculation from dewatering process to digester;

- In the tertiary treatment for wastewater sterilization to eliminate pathogens.

How does SewaTOR work and how can it optimize your wastewater treatment plant?

SewaTOR breaks through technology defragments the sewage sludge out of the different WWTP stages to create a more homogeneous material, with less viscosity, much easier and fast to process and transport. This cuts down WWTP energy consumption, lowering electricity related CO2 emissions and increases the biogas production yield leading to a more resource efficient WWTP.

The processing time is greatly reduced enabling the downsizing of the WWTP and lowering CAPEX requirements. Moreover, the amount of disposed sludge decreases (up to 100%) alongside its harmful pathogen and chemical load. With its sterilization effect, also accompanied by integrated sanitization with UV-C and/or O2, SewaTOR also eliminates germs and all organic material in the discharged water accomplishing the new EU sanitation requirements, enabling water recycling, and solving the climate change scarcity problems.

herefore, SewaTOR is an innovative wastewater treatment technology that strongly contributes to accomplish the water quality required by the EU WFD in water bodies and to overcome the new challenges devised by the EEA for the European WWTP industry in the 21st century.