SewaTOR®

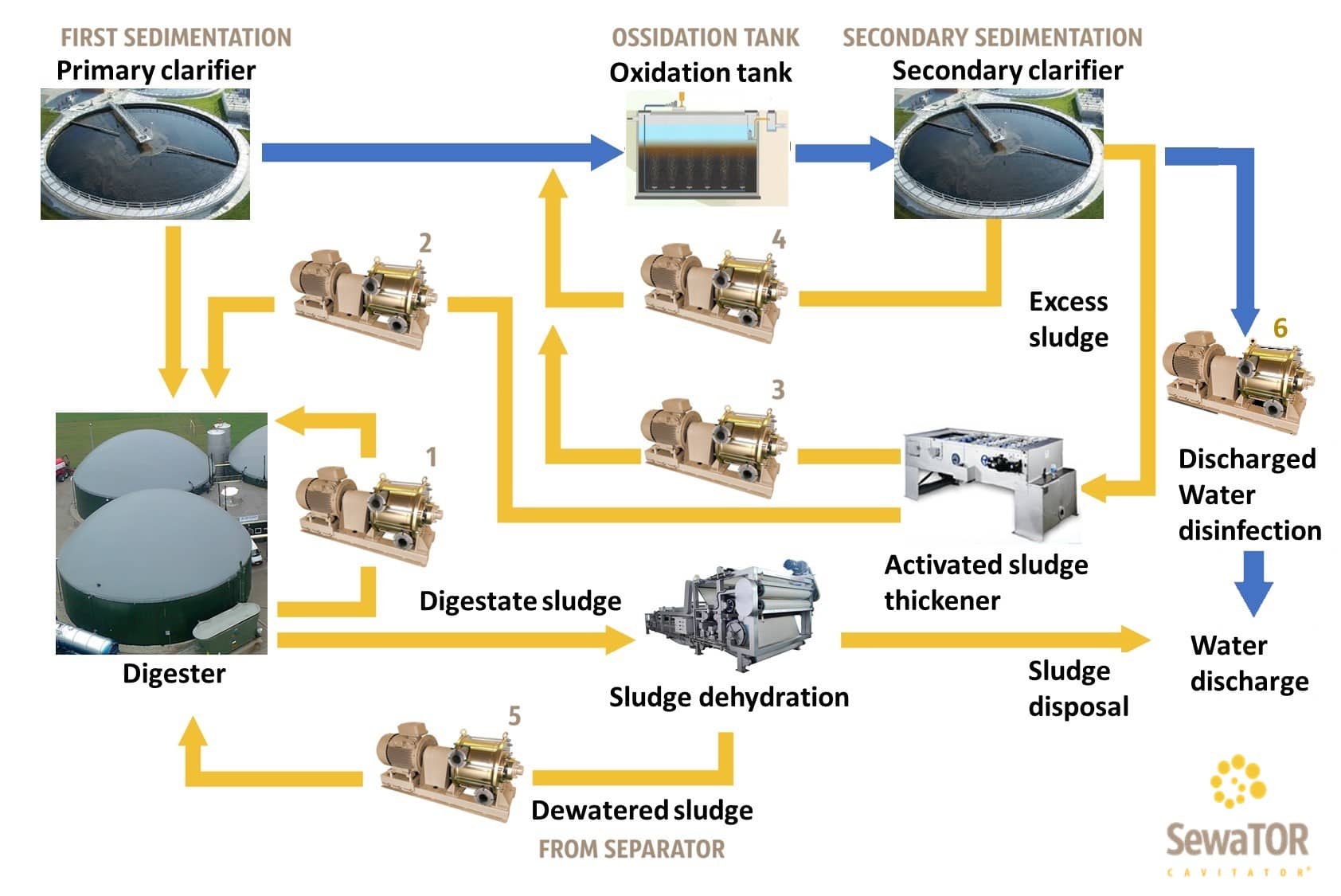

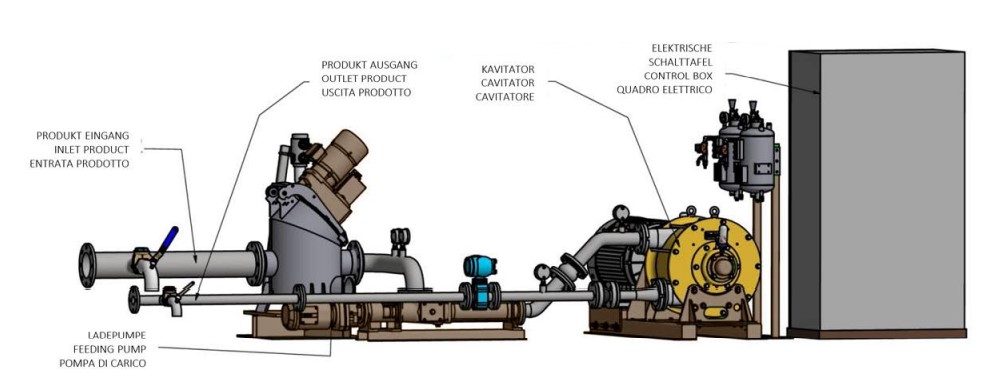

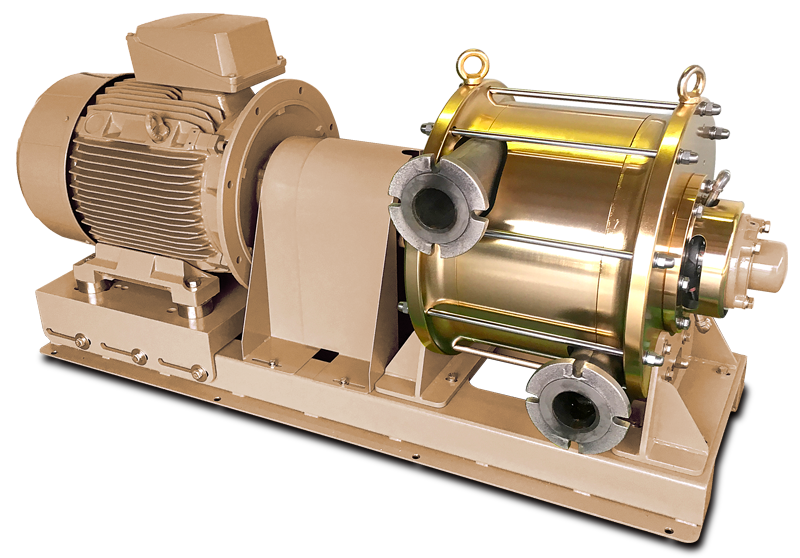

SewaTOR® is the effective and efficient patented pretreatment technology that exploits the physical phenomenon of Contrica® Cavitation. SewaTOR® has been designed to work continuously and meet the quality standards of all manufacturers and users of WWTP in the world. SewaTOR® can be supplied as a component to be integrated on the plant or on a skid / container with pump, electrical panel, PLC and sensors.

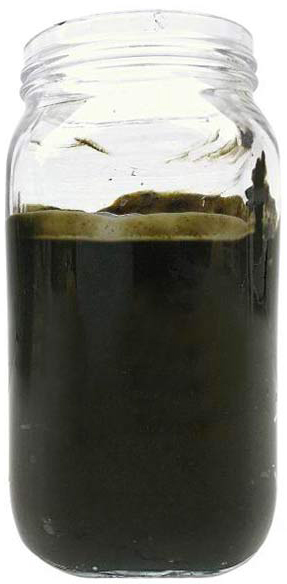

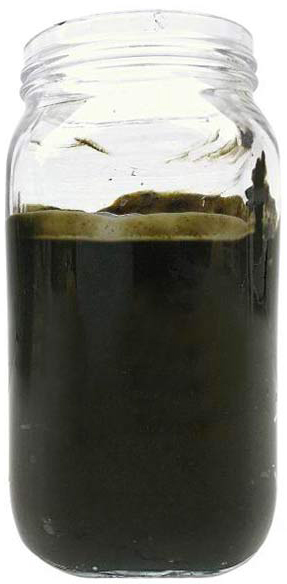

BEFORE___>___AFTER

Public and private companies with waste water treatment plants

BEFORE___>___AFTER

OPTIMIZE DISPOSAL COSTS:

SewaTOR® increases the disintegration of particles and reduces the sludge to be disposed of and voluminous foams.

INCREASES THE YIELD:

SewaTOR® maximizes the yield of oxidation and digestion processes and reduces the retention time.

REDUCES CONSUMPTION:

SewaTOR® definitely improves viscosity and reduces mixers consumptions.

Public and private companies with waste water treatment plants

OPTIMIZE DISPOSAL COSTS:

SewaTOR® increases the disintegration of particles and reduces the sludge to be disposed of and voluminous foams.

INCREASES THE YIELD:

SewaTOR® maximizes the yield of oxidation and digestion processes and reduces the retention time.

REDUCES CONSUMPTION:

SewaTOR® definitely improves viscosity and reduces mixers consumptions.

BEFORE > AFTER